Product description

FK6 ASD - Double laminar sealing rings

for bores

Application “FK6 ASD” Outside clamping double rings (2 rings = 1 set)

In contrast to the single wound laminar sealing rings “FK 3″, “FK6″ laminar rings are double wound. They are used as grease seals for roller and plain bearings. They are also used as a protection seal in front of hermetically acting seal arrangements. The “FK 6″ laminar rings must meet special sealing requirements against grease leakage and against dust, dirt and splash water ingress. “FK 6″ laminar rings provide a uniform radial tension and, in contrast to the “FK 3″ laminar rings, they have no axial joint gap. The combined ring sets “FK6 ASKD” (additional sealing of the groove base diameter) optimize the sealing effect due to the increased labyrinth effect.

The “FK6 ASD” or “FK6 ASKD” assemblies are normally preferred over the “FK6 ISD” or “FK6 ISKD” due to their easier ring installation into the grooves of the ring carriers. Depending on the applications or the technical requirements, the ring carriers can be manufactured from steel, cast iron, light alloy or plastics.

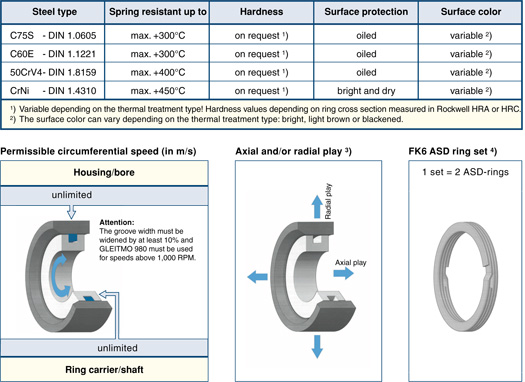

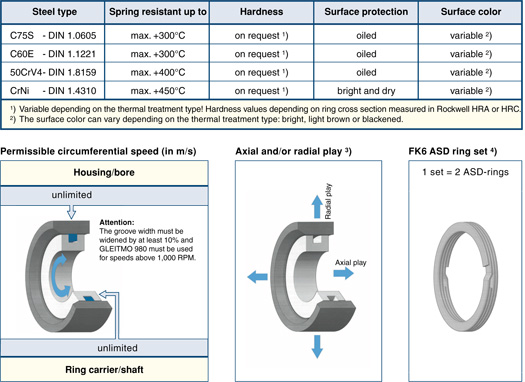

Ring materials

Axial and/or radial play:

The groove width “A” must be widened by twice the play if play occurs in the area of the rings. The groove base diameter “D2″ must be reduced by the radial play if radial play occurs. Damage to the rings and the surrounding components occurs if this is not adhered to. It is recommended to use the full groove width tolerances, especially in the case of thermal expansion.

Installation information:

Click here.

Order information:

The ring diameter information must match the housing or bore diameter dimensions “D1″ for all inquiries and/or orders. The rings can be ordered individually or in sets (1 set = 2 ASD rings).

Run and installation tests:

Run and installation tests under operating conditions must be performed in each case before standard production of our laminar rings can begin to determine whether the desired sealing effects can be achieved.